Chapter TPU ring rolling

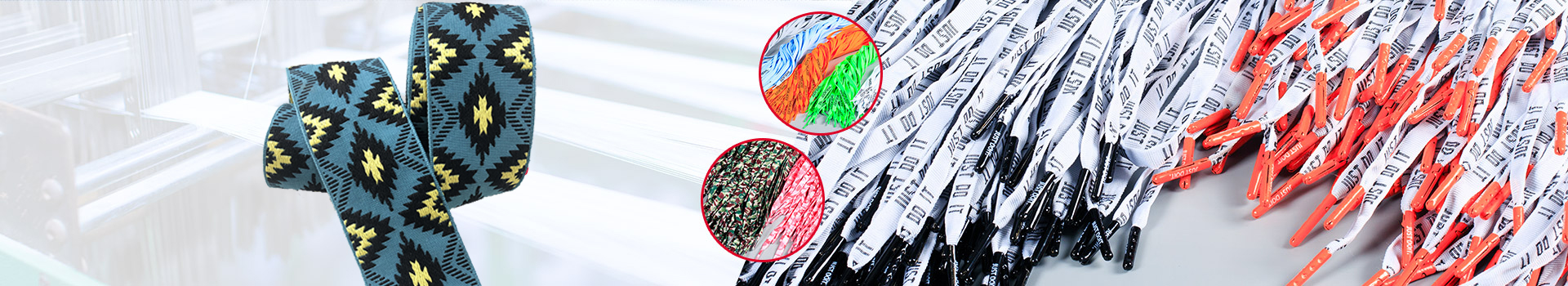

Rope belt manufacturers rope belt widely used, the rope belt processing equipment also requires a high degree of automation, the effect of exquisite, traditional ribbon shear is the use of cold shear, hot shear principle, shear effect has rough edge, loose edge, cut uneven or yellow, coke. In order to improve this situation, the use of ultrasonic principle shear ribbon, can achieve full automatic shear, ultrasonic sealing, not yellow, coke, to achieve the ideal effect.

On the development of new composite nonwoven materials, the United States developed a new type of cotton fiber composite non-woven fabric, the surface of cotton and hot glue non-woven polypropylene fiber, and the composition of spun-bonded fabric two layer or three layer composite material, feel is similar to pure cotton knitted fabric products, has the very good strength and elongation, water absorption and water retention, core faster absorption, pilling performance advantages of small, after finishing, elongation was 50% of the instantaneous elastic recovery rate can reach 83% ~ 93%, and is suitable for making medical gowns and disposable underwear.

In addition, the new generation of biochemical protective clothing developed by the us army makes full use of the advantages of three fabrics, namely woven, knitted and non-woven. The outer layer of protective clothing is tear resistant nylon/cotton fiber poplin, which has been treated with water repellent. The lining is non-woven fabric with activated carbon; The inner layer is tricot warp knitted fabric. Compared with the current protective clothing, the clothing provides soldiers with special protection against chemical protection, and at the same time, the clothing is more convenient, lower cost, can withstand at least three times of washing.

In the 70 s, knitting warp knitting, weft knitting technology, has been widely used in the rope belt. In 1973, the successful trial production of knitted nylon wide belt. In 1982, it began to introduce Italian crochet machine with advanced technology and wide variety of production, especially suitable for thin decorative belt fabric, such as lace, elastic belt, window screen, decorative belt and so on. The basic technological process is: bleaching and dyeing - winding - weaving - ironing - packaging.

Before the 0 s, the billet of fire hose was woven with flat loom. In the second half of 1974, the industry organization tube billet weaving development team, according to the principle of knitting, with warp/weft woven, rely on knitting yarn in the knitting process, using cylindrical arc and subsidence of knitting yarn, will not be mixed of warp and weft yarn into a whole, and become a line by line knitting tubular knitted fabric, plastic coated products outlet pipe and high-pressure fire hose production technology level in the country.

Scan is watching us

HOMEABOUTPRODUCTNEWSCASECONTACT

The phone:0760-23335277

email:Jerry@zsnanyi.com

Mobile phone:13702509450

address:No. 18, ma shi road, ma ling administration district, zhongshan shinan district, guangdong province