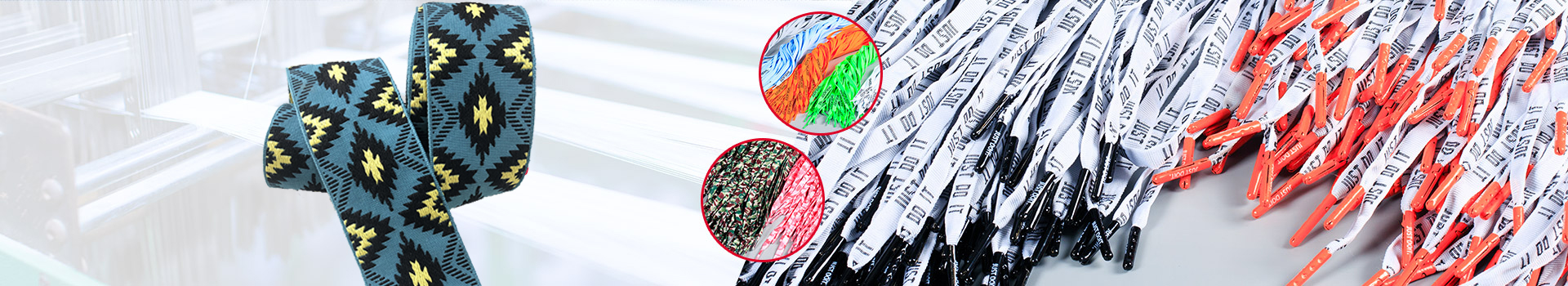

Wrist rope

But because the ribbon selection ribbon printing, printing processing screen is not a simple problem. In addition to consider screen, but also consider the ink, substrate cost and other related constraints. Enjoy the selection of the method and pay attention to the problem, choose the appropriate screen to be handy. Screen selection should pay attention to the following aspects.

(1) first consider the degree of difficulty of ink through the screen, generally choose to consider this aspect is more. Middle color ink to use transparent ink, fibrillation is expected to pull more subtle, and the ratio of relative fibrillation material chromatophore, which causes the ink, the ink when using high mesh screen can also be a good pass, general plastic ink better through sex, special-purpose inks, ink material high concentration of, although is a thin child its through sex is relatively poor.

(2) if the ribbon printing, ribbon printing lattice belt pattern, printing substrate surface rough, generally use a lower mesh screen. Such as leather, canvas, foam, wood and other materials printing. Due to the substrate surface rough, ink absorption is strong so to use a low mesh screen, to ensure that enough ink through.

(3) according to the original text and text line fine selection screen. Contrary to the above, fine lines in general to choose high mesh mesh mesh.

(4) choose screen even consider the cost, in the premise of meeting the printing requirements, try to choose a lower price screen.

The feature of this function is to be able to accurately request a weft dongguan loom action, and this action has nothing to do with the trigger time of the launch button. In the case of inching, press the start button for the next time (press and release immediately or press and release again after a pause), and the loom will perform a normal weft throwing motion and return to the state before triggering the start button to stop the machine. Press the button again, do a normal filling throw and stop the planning before the trigger button.

In the case of continuous operation, press the start button and the device will run. When the stop switch is pressed at any time, the device will stop exactly at the set position. In addition to manually pressing the stop switch, the loom will stop exactly at the set stop position if the signals including stop of warp breaking, stop of winding, stop of time limit or stop of length limit can promote the stop of the loom.

If every time the demand stops to the azimuth in the figure above, it is also possible to set the exact stopping time according to this azimuth, that is, every stop will be based on this azimuth as the fixed stopping azimuth. Of course, there are far more than these two kinds of position, can be arbitrary according to the needs of the set. If there is a demand to welcome and zhizhi weaving belt professional technical service center contact, timely promotion of your equipment, in the progress of operators and users experience together, to reduce the occurrence of defective guangdong weaving belt, the progress of production power.

Scan is watching us

HOMEABOUTPRODUCTNEWSCASECONTACT

The phone:0760-23335277

email:Jerry@zsnanyi.com

Mobile phone:13702509450

address:No. 18, ma shi road, ma ling administration district, zhongshan shinan district, guangdong province