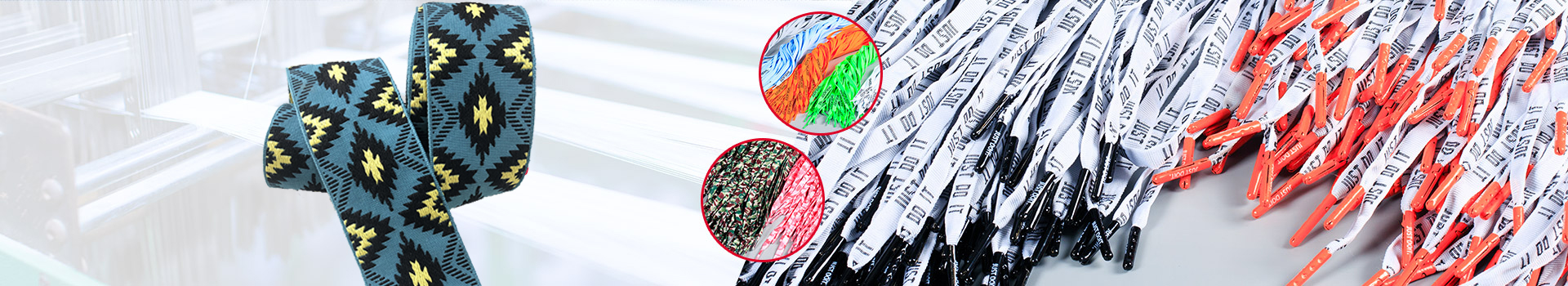

Manual tassel

The ribbon is twisted and the yarn is twisted to form a bobbin (a coil). The weft is twisted into loops and the ribbon is woven on the loom. In the 1930s, weaving belts for hand-pulled wooden looms and iron-wood looms. In the early 1960s, the 1511 loom was converted into a ribbon loom, which is still widely used. Due to the small width of the belt, the weaving methods are different, including single, double and dozens of strips, single layer and double layer.

In 1967, the worker-oriented research group successfully designed and manufactured a high-speed single non-woven belt weaving machine by itself, which realized that the weaving belt did not need shuttle, the process was shortened, the floor area was small, and the labor productivity was improved. It was a pioneering work in the history of Chinese ribbon weaving technology.

In the 1970s, due to the promotion of continuous dyeing and ironing machine, the processing of colored belts, from the traditional process of dyeing and weaving first, to the development of dyeing and dyeing first, weaving and bleaching first, processing after ironing continuous, weaving technology into the mechanization of large-scale production. In the early 1980s, the industry introduced high-speed non-woven ribbon weaving machines from Switzerland, Italy and Germany, finishing and ironing machines, winding machines and warp warping machines, and the ribbon weaving technology entered a new stage of development.

The improvement of weaving technology brings about the upgrading of products. In 1979, the successful trial production of sd9-9 rubber ingot belt made the rubber ingot belt end its dependence on import. In 1980, sd-81a and type B rubber ingot belt was developed, which has the characteristics of soft, light, thin, firm, small elongation, small impact, short and flat joint. At the beginning of 1990, the trial production of safety belt for santana car was successful. After more than two years of research and trial production, the product quality reached qc49-92 and tl-vw470 standards.

Woven belt manufacturers in the light conveyor belt products are widely used in the field, the product performance requirements are very fine, different industries of performance requirements. Different application environments and applications of downstream industries have great differences in the performance requirements of light conveyor belts, which put forward high requirements on the technical capabilities of enterprises. In this regard, enterprises need to modify coating materials, deal with skeleton fabric and find suitable substrate materials and manufacturing process to achieve different conveyor belt performance, and the performance of some high-end products also need to be combined with advanced calendering process to achieve.

Scan is watching us

HOMEABOUTPRODUCTNEWSCASECONTACT

The phone:0760-23335277

email:Jerry@zsnanyi.com

Mobile phone:13702509450

address:No. 18, ma shi road, ma ling administration district, zhongshan shinan district, guangdong province