Good nylon ribbon to the long time need to use more strength, and the poor is very easy to stretch. So we have to choose a stronger nylon ribbon will be more durable. Packing tape, the scientific name of polypropylene, is a kind of light plastic in common, the main material of packing tape is polypropylene wire-drawing resin, because of its good plasticity, strong breaking tension, bending resistance, light specific gravity, easy to use and other advantages, processed into the binding tape, has been widely used in various fields. ,

For polypropylene, there are many brands of polypropylene, and packaging tape production (good effect) USES polypropylene raw material of brand T30S. Packing tape appearance: translucent to opaque, transparent film texture. Flammability: flammable in flames. Slowly extinguish or continue to burn after leaving the flame. When burning, the upper end of the flame is yellow, the lower end is blue; Melting, dripping phenomenon. You can smell paraffin.

Decorative methods, weaving technology also use cloth paste, embroidery, blue printed cloth, cashmere embroidery and other processes, to make it more colorful. Decorative embroidery, cloth paste, cashmere embroidery or colorful straw woven patterns on baskets made of straw or corn husk show nobility in elegance. The corn-husk fastening basket is made of blue calico, which makes the corn-husk fastening weaving more white and exquisite. On the cornhusk woven wall hanging, decorated with corduroy cloth paste pattern, the technique is novel.

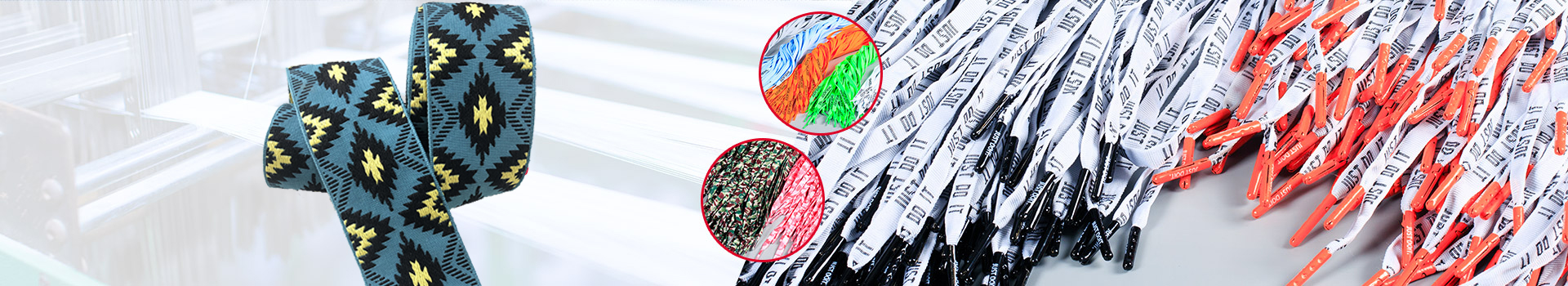

After forming the weft tube with warp and weft winding, the weft tube is inserted on the fixed tooth seat of the braiding machine. The weft tube rotates and moves along the figure 8 track to pull the yarns to cross weave with each other. Generally, the number of spindles is even, the woven ribbon is tubular, the number of spindles is odd, the woven ribbon is flat. Spindle weaving technology has been applied in old China. The number of ingots varies from 9 to 100, depending on the equipment. The basic technological process of weaving is as follows: bleaching, dyeing, weft winding, weaving, cutting, and packaging. Since 1960, many technical innovations have been carried out on braiding machines, such as enlarging the diameter of peach board, installing automatic stop device of elastic break, and replacing iron ingot with nylon spindle. The improvement of these devices has increased the speed to 160 ~ 190 RPM, doubled the stand rate and greatly improved the product quality.

Scan is watching us

HOMEABOUTPRODUCTNEWSCASECONTACT

The phone:0760-23335277

email:Jerry@zsnanyi.com

Mobile phone:13702509450

address:No. 18, ma shi road, ma ling administration district, zhongshan shinan district, guangdong province