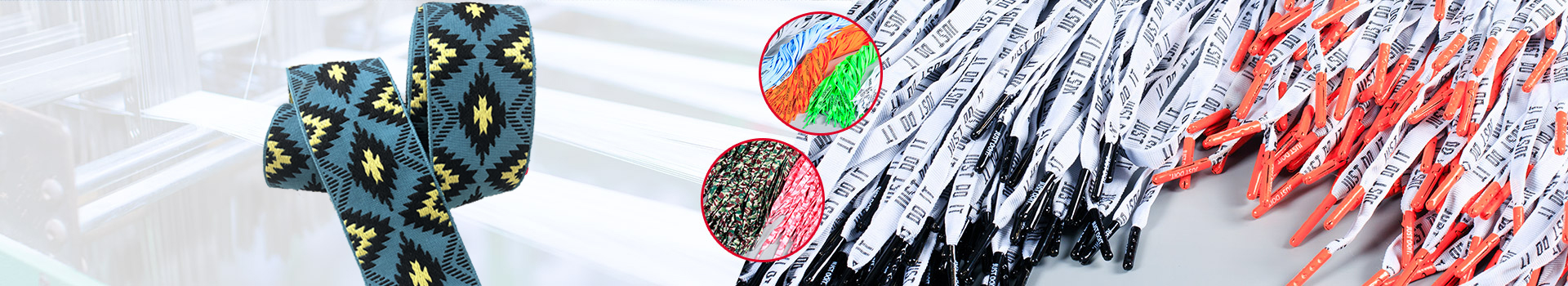

The main service of rope belt factory is to provide all kinds of rope belt products for the enterprises of clothing, ornaments, gifts and crafts. The rope belt factory product is various, the rope belt product has the tradition and the modern union, the fashion element highlights the characteristic. In the production process, has abandoned the traditional mechanical equipment production, the use of advanced integrated equipment production, with high process accuracy, large output advantages, products.

The main raw materials of sanyai products are:

Artificial cotton: processed from wood, cotton, reed, etc., with good dyeing function, good fastness, not easy to produce static electricity, fuzz and pilling rubber silk.

Hemp: it is a kind of plant fiber, good moisture absorption with rope, fast wetting, not easy to happen electrostatic heat conduction, quick heat dissipation, more water resistant, heat resistant.

Nylon: nylon, good dyeing property in synthetic fiber, simple rope, outstanding waterproof and windproof function, high abrasion resistance, good strength and elasticity.

Vinylon: the rope looks and feels like cotton cloth, with poor elasticity, good moisture, small specific gravity and thermal conductivity, good abrasion resistance, chemical resistance, sunlight resistance and other functions.

Polyester: elasticity and recovery, fabric crisp, no wrinkle, good shape preserving, high strength, good elasticity, some light resistance, simple electrostatic and dust absorption poor moisture absorption.

Mixed hemp: fine in texture, firm and durable, clean in face and soft in hand. Acetate fiber: it is made of natural material containing cellulose through chemical processing. It has the characteristics of silk. The rope has excellent elasticity and elastic recovery function.

The products produced by the rope and belt factory are used for making socks, which have the function of anti-aging and anti-corrosion, and the woven socks still have excellent resilience after being exposed to the sun and washed. The socks woven with the product are very comfortable in the tightness of the rims, so that the socks will not go down by themselves or leave strangulation marks on the skin. Rubber rubber factory products are environmentally friendly fibers, no skin irritation. The weight of the socks is one third of the ordinary rubber string, which can greatly reduce the use of rubber string. The rate of defects in the stocking production process is significantly lower than that of ordinary elastic thread, which can effectively reduce the production cost of the factory.

Nylon ribbon adopts imported nylon yarn and environmental protection dye, and advanced dyeing and finishing equipment and technology production, bright color, good wear resistance, soft feel, strong pull and gloss and other unique advantages of nylon ribbon. Nylon ribbon in the use of strong durability, sustainable ten years do not change. Various weaving methods can also be developed according to the needs, such as plain, herringbone, twill, twill overlock, hollow belt (hollow belt), fine pit lines, etc. Widely used in handbags, leather goods, luggage, hanging belt, outdoor supplies, baby carriages and other products.

Scan is watching us

HOMEABOUTPRODUCTNEWSCASECONTACT

The phone:0760-23335277

email:Jerry@zsnanyi.com

Mobile phone:13702509450

address:No. 18, ma shi road, ma ling administration district, zhongshan shinan district, guangdong province