Ribbon embroidery is embroidery. It is in a long period of history by the world's craft gradually developed, embroidery lace can be divided into machine-embroidered lace and hand-embroidered lace two categories, machine-embroidered lace is the basis of hand-embroidered lace developed from the type of large production lace.

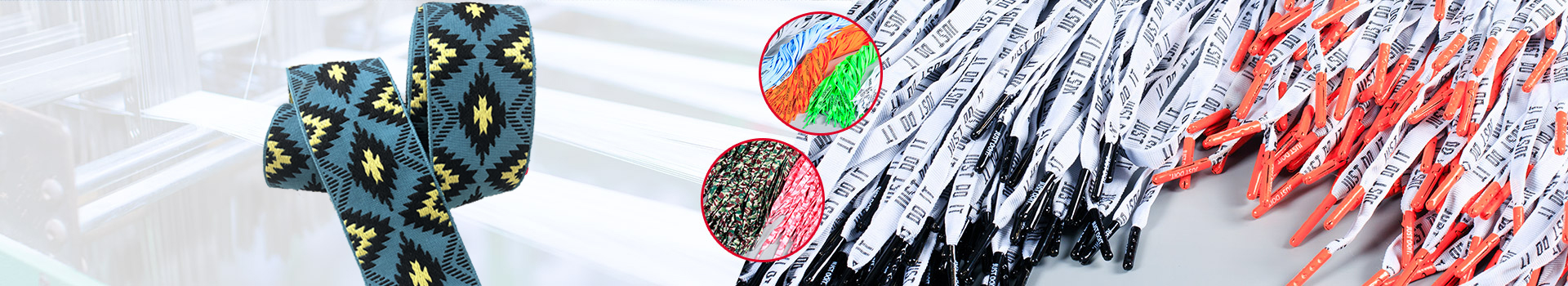

There is a very common color scheme and graphic patterns in all ethnic groups (typical jacquard ribbons are good examples). Chinese embroidery has a long history and occupies an important position in the national traditional craft. Hand embroider edge is craft of our country traditional craft, produce power low, embroider grain often easy hair make uneven phenomenon, embroider also can intermingled between good and bad. However, the mottled too messy, more colorful, flower back longer lace is not a craft, and hand embroidery than machine embroidery rich three-dimensional feeling. In China, hand embroidery has a long history. Besides the well-known four famous embroideries in China, su embroidery, xiang embroidery, shu embroidery and yue embroidery, there are also han embroidery, lu embroidery, hair embroidery, cashmere embroidery, qin embroidery, li embroidery, shen embroidery and other outstanding techniques of minority embroidery.

Fabric arrangement can be woven into different patterns or patterns, such as tabby arrangement of grain appearance, twill arrangement of oblique pattern and satin arrangement of float. The arrangement not only affects the appearance of the fabric, but also affects the style of dongguan fabric and the quality of the fabric. Such as plain fabric texture firm; Satin fabric is smooth and even, lustrous and soft.

The density of woven fabrics refers to the number of yarns arranged per unit length of the fabric in both directions. The fabric density has a great influence on the wearing function, such as strength, elasticity, feel, body bone, breathability and moisture permeability, as well as the breakage rate during weaving. The high density of warp and weft makes the fabric tight, solid, firm, wear-resistant and firm.

Color fastness is an important goal of good or bad quality of ribbon, the first emphasis is on color fastness of conflict resistance, sweat resistance, water resistance, light resistance, washing resistance. First according to the use of goods to determine which items, according to the need to tailor. The problem that ribbon factory gives output decolorizing ribbon can be big or small, if the ribbon that USES at dress fittings decolorizes when washing, can whole garment, perhaps the garment that washes together was polluted at the same time. Decolorized ribbon can give people a very serious sense of disgust.

So-called color fastness refers to dyed textiles in the physical and chemical effects, color adhere to the degree of fastness, that is, dyed textiles color fastness by external influence is called dyeing fastness. After the experiment, the color change of the sample and the color staining degree of the white cloth were used to indicate the color fastness.

Scan is watching us

HOMEABOUTPRODUCTNEWSCASECONTACT

The phone:0760-23335277

email:Jerry@zsnanyi.com

Mobile phone:13702509450

address:No. 18, ma shi road, ma ling administration district, zhongshan shinan district, guangdong province