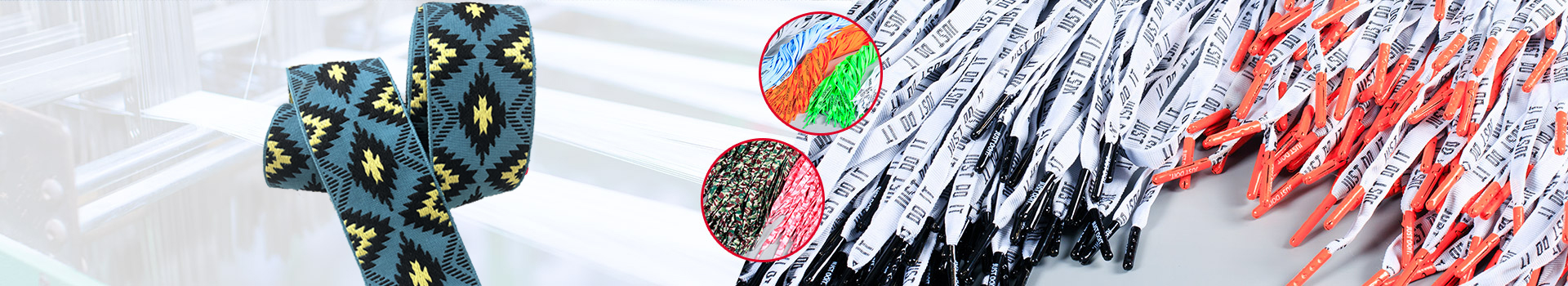

Professional research and development of functional ribbon manufacturers, products can resist UV, waterproof, UV resistance, fire retardant, mildew resistant sweat stains. Can be customized to any size and color ribbon, thin can achieve 0.15mm, width can achieve 6000MM, thickness can reach 4mm. Weaving technology: originated from advanced weaving technology in Taiwan, with 15 years of working experience, the company has accumulated a number of professional technical talents, and has set up a development department to continuously bring forth new technologies and improve product types and quality.

The ribbon is made of narrow or tubular fabric from various yarns. There are many kinds of ribbon articles, which are widely used in clothing, shoe materials, luggage, industry, agriculture, military supplies, transportation and other industrial departments. In the 1930s, the ribbon was produced by manual workshops with cotton thread and hemp thread as raw materials. After the founding of the People's Republic of China, the raw materials used for weaving ribbons were gradually developed to polyamide, vinylon, polyester, polypropylene, spandex, viscose, etc., forming three major types of processing technologies of weaving, knitting, knitting, fabric structure has plain, twill, satin, jacquard, double layer, multi-layer, tubular and joint organization.

Woven by ribbon manufacturer: warp and weft interwoven. After twisting, the yarn is turned into a winding, and the weft is wound into a winding, which is woven on the loom. In the 1930s, weaving belts for hand-pulled wooden looms and iron-wood looms. In the early 1960s, the 1511 loom was converted into a ribbon loom, which is still widely used. Due to the small width of the belt, the weaving methods are different, including single, double and dozens of strips, single layer and double layer.

In xi 'an banpo, temple bottom ditch, sanli bridge and other neolithic ruins unearthed pottery, printed with "ten" character lines, "people" character lines, clearly show that it is made of bamboo mat printed on, some also found that the bottom of the ceramic pot adhesive bamboo mat residue. A reed mat unearthed at hemudu site in yuyao, zhejiang province, has a history of about 7,000 years. In 1958, the bamboo weaving unearthed at the site of the late neolithic age in qian shan Yang village, huzhou, zhejiang was even more amazing, with about 200 pieces, most of which were made by scraping and grinding. In this period, the weaving technology was quite exquisite, including "man" shape, "ten" shape and diamond and plum shape. The variety of implements has basket, basket, basket, etc.

In zhou dynasty, it was very common to knit gampa mat. In the han dynasty, Lin cao (also known as Lin, malan, rush grass) was woven as mat, produced in sanfu (now central shaanxi), hedong (now xia county, shanxi) and other places. In tang dynasty, straw mat production was very common. Rattan weaving in fujian and guangdong, willow weaving in cangzhou, hebei, wheat straw weaving in puzhou, shanxi (now yongji, hejin and other places) were all famous handicrafts. Among them guangdong rattan plaits still has the curtain that weaves design of flowers, fish insect, bird bird. Song dynasty, zhejiang dongyang bamboo varieties have dragon lantern, flower lamp, walking lantern, incense basket, flower basket, etc., can weave calligraphy and painting, patterns, delicate technology, in each square inch (11 square centimeters) of the area can weave 120 roots of bamboo strips, some also decorated with gold line. During the Ming and qing dynasties, straw weaving, rattan weaving and bamboo weaving developed in zhejiang, jiangsu, hunan, sichuan, fujian, guangdong and other places and were exported at the end of the 19th century.

Scan is watching us

HOMEABOUTPRODUCTNEWSCASECONTACT

The phone:0760-23335277

email:Jerry@zsnanyi.com

Mobile phone:13702509450

address:No. 18, ma shi road, ma ling administration district, zhongshan shinan district, guangdong province